By Robert Metzke, Chief of Staff Innovation & Strategy and Head of Sustainability, Philips

All over the world, we are seeing a growing consensus that it’s ‘now or never’ when it comes to saving the planet for the generations to come. The time for talking is over. As the public and private sectors explore what we need to do to meet the climate targets set out in the Paris Agreement, three of the key approaches to drive down emissions are to:

Broadly and systematically adopting EcoDesign practices is pivotal for all three approaches.

More and more, our healthcare customers don’t just want us to provide them with health technology solutions and services. They are looking for a responsible partner who can help them reduce their environmental impact and embed sustainable practices in their day-to-day operations.

When we are talking with them, they immediately grasp what we mean by switching from the destructive ‘take-make-break’ cycle of the linear economy to the virtuous ‘make-use-return‘ loop of a circular economy. The logic is clear and compelling. And they’re intrigued by the notion of EcoDesign, but many are less sure what it actually entails, and are keen to find out more. So what is EcoDesign? And why does it matter?

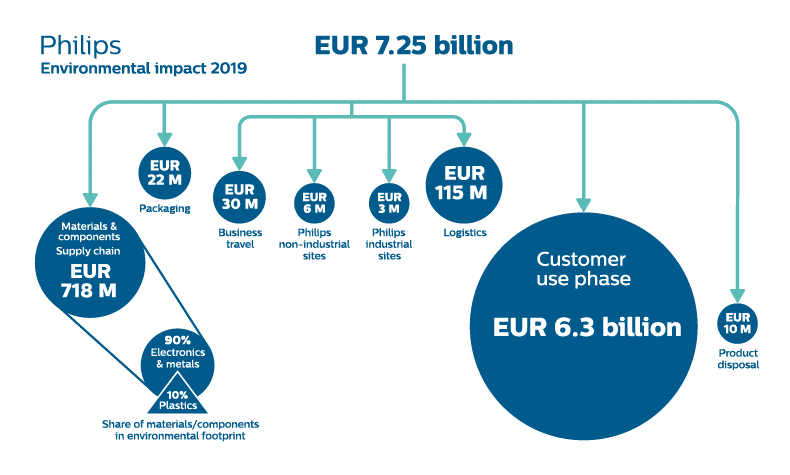

Each year at Philips we publish an Environmental Profit & Loss account (EP&L), which expresses the total environmental impact of our activities and products – from product design to final disposal by the user – in monetary terms. This makes things very concrete. The EP&L provides us with valuable insight into the main environmental hotspots and the areas where we need to innovate in order to reduce our environmental impact.

If we look at our 2019 EP&L above, our products – that’s everything except the circles denoting business travel, our sites and logistics – account for 97% of our total environmental impact. Of that, around three quarters is attributable to energy consumption during the customer use phase. Materials account for roughly 20% of a product’s impact, followed by packaging and end-of-life (less than 5% of the product lifetime impact).

This is where EcoDesign comes in …

The difference between EcoDesign and conventional design is the clear goal – right from the outset of the innovation and design process – to reduce the total environmental impact. First introduced at Philips as far back as 1994 (long before the European Union launched its first framework), EcoDesign is an approach that holistically considers all aspects of product development and design. On average, 80% of a product’s total environmental impact – including energy during use and material impact – is determined in the design phase.

Here, we can implement sustainability-led design decisions that can make a decisive difference. To this end, it is vital that the innovation development and design teams have a shared understanding of the ‘impact reduction’ ambition, and how it translates into clear priorities and requirements for them to focus on. So, how do we do this?

We use Life Cycle Analysis thinking as the backbone for our EcoDesign process. This enables us to determine the environmental impact at each stage of a product's life – from raw material extraction through materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling.

By consistently applying Life Cycle Analysis, we have been able to identify and realize significant improvements, lowering environmental impact. The environmental hotspots are captured in what we call Green Focal Areas – Energy, Packaging, Substances, Weight & Materials, and Circularity.

Energy: Energy consumption is often the single most important factor in determining a product’s lifecycle environmental impact. By improving the energy efficiency of a product, we can reduce its energy consumption and carbon footprint.

Packaging: Lightweight and low-volume packaging, use of recycled and/or bio-based, biodegradable content, and better recyclable packaging all help minimize resource consumption and environmental impact over the life cycle of the packaging.

Substances: Products are made using a range of substances, some of which may have an impact on the environment. By minimizing or eliminating the use of hazardous substances, we can reduce our products’ environmental impact.

Materials: By reducing the amount of materials we use, we can use fewer resources and less energy during manufacturing and/or transportation. Also the choice of materials – e.g. precious metals, bio-based, bio-degradable materials – can have a positive or negative environmental impact.

Circularity: Circularity refers to the potential of a system, product or component to contribute to the circular economy. It is calculated by assessing environmental performance over multiple life cycles, taking into account, for example, the recovery of materials and their reuse in new products. Upgrading, serviceability, refurbishment, spare parts harvesting, increased recycled content and recyclability – these all help to reduce the consumption of resources. Circularity also includes product lifetime; longer lifetime of products reduces the resource consumption and transportation emissions associated with the introduction of new products.

EcoDesign represents a complex yet exciting challenge for our designers and product engineers. In their everyday decisions they strive to optimize the balance between sustainability, quality and user experience. This at an affordable price that can allow us to reach and improve billions of lives. We no longer consider one product life: we take into account and plan end-of-life recovery strategies in the early stages of the design process. So, applying EcoDesign requires a shift in mindset: from designing for ‘today’ to designing for ‘tomorrow’ and beyond.

We refer to EcoDesigned products that offer a significant environmental improvement in one or more of these Green Focal Areas as ‘Green Products’. With sustainability a central element of our business strategy, we set ourselves the target of having Green Products account for 70% of total sales by the end of 2020, and we’re on track to achieve it.

More and more, our customers – both healthcare and retail – are demanding solutions that are kinder to the environment. At the same time, especially in our (post-)COVID world, we face new concerns and dilemmas. For instance: How to reconcile the need to get rid of plastics/packaging with the need for safety and hygiene? Either way, we have to find innovative ways to empower our customers to make responsible choices – not having to choose between a product looking good or being good for the environment. It has to be both, not one or the other.

Moving to a low-carbon circular economy also requires a different regulatory mindset. Regulation, so often an enabler, can sometimes also be a constraint. At Philips, for example, we still face regulations that limit the full potential of refurbishment by hampering cross-border transport of used equipment to our refurbishment facilities. Or import restrictions on recycled plastic materials we could use in the manufacture of new devices.

In the immediate future, we at Philips will continue to focus on doing everything we can to help bring us closer to our shared ambition to limit global warming to 1.5 °C.

We will be carbon-neutral in our global operations by the end of this year, and source 100% of our electricity from renewable sources. At the same time, we will continue to reduce the climate impact of our products by increasing the use of recycled plastics and recyclable materials. We will continue to phase out chemical/scarce substances. And we will continue to make our packaging easier to recycle and re-use.

We are also developing new design methodologies to embed circular design thinking in our development processes, often in collaboration with universities and other companies.

As we focus on improving the energy and resource efficiency of our products and solutions, it is our hope that:

Author: Robert Metzke